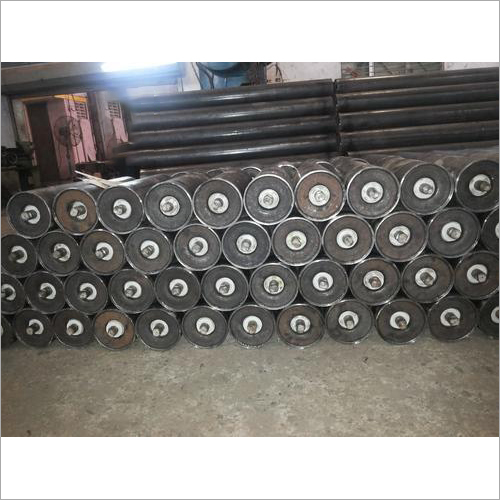

Impact Conveyor Idler

Impact Conveyor Idler Specification

- Features

- Heavy Duty, High Impact Absorption, Durable

- Belt Type

- Flat / Troughed

- Surface Finish

- Powder Coated or Painted

- Thickness

- Roller Shell Thickness 4-12 mm

- Material

- Rubber Coated Steel / Mild Steel

- Type

- Impact Idler

- Structure

- Roller Conveyor

- Belt Conveyor

- Compatible

- Roller Conveyor

- Compatible

- Resistant Feature

- Corrosion and Impact Resistant

- Load Capacity

- Heavy Duty (Up to 3000 kg)

- Speed

- Up to 3.5 m/s

- Usage & Applications

- Used at loading zones to absorb impact and protect conveyor belt

- Number of Rollers per Idler

- 3 (Standard Triple Roller Arrangement)

- Roller Length

- 200 mm 2200 mm

- Temperature Range

- -20C to +80C

- Shaft Diameter

- 20 mm 40 mm

- Sealing

- Double Labyrinth Sealed

- Color

- Black/Green as per requirement

- Mounting Type

- Bracket / Frame Mounted

- Roller Diameter

- 89 mm 219 mm

Impact Conveyor Idler Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 7 Days

About Impact Conveyor Idler

Impact Conveyor Idler that we proffer is one of the key spare part of the industrial conveyor system. This type of idler has excellent loading capacity, great gripping surface and ideal dimension, for which ensuring mind-blowing performance of the conveyor machine along with maximum safety of loaded material. Having ideal diameter and superior shore finish, it can easily be fitted to the conveyor without putting much efforts. Moreover, the Impact Conveyor Idler can be availed in desired sizes and diameters at moderate prices.

Impact Conveyor Idler provided is an important element of conveying systems used in industry. Remarkable load strength, high coefficient of friction, and ideal measurements contribute to the best performance of the conveyor machines, as well as the highest material security. Thanks to its perfect diameter size, and the smooth finish of the products, it will not be complicated at all to install the item. By sourcing the Impact Conveyor Idler in different sizes and diameters you get high-standard quality idlers at low costs.

Optimal Shock Absorption for Loading Zones

Designed for high-impact absorption, this triple roller idler safeguards conveyor belts at critical loading zones. Its robust construction and rubber-coated rollers help distribute impact forces evenly, reducing the risk of belt damage and prolonging system life. Choose between flat or troughed belt types for versatile installation.

Heavy-Duty Construction with Reliable Sealing

With shaft diameters from 20 mm to 40 mm and shell thicknesses between 4 to 12 mm, each idler is engineered for long-lasting durability in demanding environments. The double labyrinth sealing system effectively prevents contamination, ensuring smooth operation and minimizing maintenance requirements.

Versatile Mounting and Application

Our impact idlers are compatible with both bracket and frame-mounted setups, making installation flexible across a wide array of conveyor structures. Corrosion and impact resistance, combined with powder-coated or painted finishes, ensures dependable performance in tough industrial settings throughout India and beyond.

FAQs of Impact Conveyor Idler:

Q: How is the impact conveyor idler installed in material handling systems?

A: The impact conveyor idler can be mounted using either a bracket or a frame, providing flexibility for integration into both roller and belt conveyor structures. This makes installation straightforward whether you are retrofitting existing systems or incorporating them into new projects.Q: What applications are most suitable for this idlers triple roller arrangement?

A: The standard triple roller arrangement is particularly effective at loading zones on conveyor belts, where it absorbs heavy impacts from falling material, protects the belt surface, and extends both the belt and idler lifespan in heavy-duty industrial environments.Q: When should I consider using a heavy-duty impact idler like this?

A: You should use this heavy-duty impact idler when transporting large, abrasive, or heavy materials, especially at loading and transfer points, to minimize belt damage and reduce maintenance costs under high-impact conditions.Q: Where can this impact conveyor idler be effectively used?

A: These idlers are ideally suited for use in mining, aggregate, bulk material handling, and industries where conveyors are exposed to frequent high-impact loading. They are widely supplied and installed throughout India by manufacturers, exporters, distributors, and traders.Q: What benefits does the double labyrinth sealing offer to the idlers performance?

A: The double labyrinth sealing protects the internal bearing components from dust, moisture, and other contaminants, ensuring smoother operation, prolonged service life, and lower maintenance requirementseven in harsh industrial environments.Q: How does the idler maintain durability against corrosion and impact?

A: Constructed from rubber-coated steel or mild steel with a powder-coated or painted finish, the idler offers both corrosion and impact resistance, making it suitable for long-term, heavy-duty use in a broad range of environmental conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Conveyor Idler Category

Carrying Conveyor Idler

Minimum Order Quantity : 10 Pieces

Material : Mild Steel / HDPE / Rubbercoated as per requirement

Type : Other, Carrying Conveyor Idler

Structure : Roller

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS