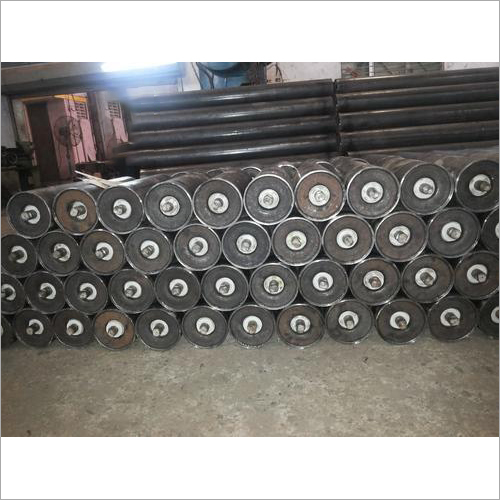

Carrying Conveyor Idler

Carrying Conveyor Idler Specification

- Features

- Low maintenance, Abrasion proof, Long operational life

- Thickness

- 3 mm to 10 mm (shell)

- Surface Finish

- Powder Coated / Painted

- Belt Type

- Flat / Troughed as per application

- Material

- Mild Steel / HDPE / Rubber-coated as per requirement

- Type

- Carrying Conveyor Idler

- Structure

- Roller

- Belt Conveyor

- Yes

- Roller Conveyor

- Yes

- Vertical Conveyor

- No

- Pneumatic Conveyor

- No

- Resistant Feature

- Corrosion Resistant

- Load Capacity

- 50 to 2000 kg per idler

- Speed

- Customized as per system design

- Usage & Applications

- Material handling in industries like mining, cement, power, aggregates, and ports

Carrying Conveyor Idler Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 7 Days

About Carrying Conveyor Idler

We offer A-one Carrying Conveyor Idler to numerous patrons. This type of idler is precisely fitted to conveyor system to provide protection to conveyor belt from hardening as well as cracking by heat. Offered idler is well featured with great abrasion & heat proof cover rubber compound. The idler can be installed with ease due to its ideal diameter, flexibility, superior finish and solid construction. In addition to this, the Carrying Conveyor Idler can be bought in secured roll packaging in desired amount at industry leading prices.

Carrying Conveyor Idler can avail themselves of the component to guard conveyor belts against the hazards of heat which causes them to harden and crack. The material used is a rubber compound that is wear-resistant and heat-stable. Because of its ideal diameter, flexibility, superior finish, and solidity, the product is easy to install. Furthermore, the Carrying Conveyor Idler is available in secure roll packaging, in sets varying from one piece to another at reasonable market prices.

Advanced Engineering for Longevity

Our Carrying Conveyor Idler incorporates precision manufacturing and quality materials, ensuring optimal wear resistance and long operational life. Equipped with labyrinth sealing and stringent ISO 9001:2015 quality compliance, it operates efficiently with minimal noise and virtually no maintenance, even in harsh industrial surroundings.

Tailored for Industrial Versatility

Designed for a broad spectrum of industrial applications, this conveyor idler fits flat and troughed belt types and supports both belt and roller conveyor systems. With customizable speed and surface options, it can be integrated seamlessly into existing material handling setups to improve productivity and reduce operational costs.

FAQs of Carrying Conveyor Idler:

Q: How do I install and replace the Carrying Conveyor Idler?

A: The idler is engineered for straightforward installation and replacement, fitting standard belt and roller conveyor structures. Simply align the idler with the conveyor mounts and secure it as per standard installation guidelines. No special tools or complex procedures are required.Q: What applications are best suited for this conveyor idler?

A: This idler is ideal for material handling in demanding environments such as mining, cement, power generation, aggregates, and port operations. Its corrosion-resistant build and robust load capacity ensure reliable service across various industries.Q: When should I consider using this specific idler model?

A: Consider this model when you require low-maintenance, durable idlers for medium to heavy loads (502000 kg), need corrosion resistance, and demand a long lifecycle with minimal downtime. Its particularly suitable where ISO 9001:2015 compliance and quiet operation (<60 dB) are critical.Q: Where can I use this idler within a conveyor system?

A: This idler is designed for use in belt conveyor systems that require flat or troughed belt types. It can be installed at carrying sections in both straight and inclined conveyors but is not intended for vertical or pneumatic conveyor applications.Q: What benefits does the labyrinth seal provide?

A: The labyrinth sealing system safeguards internal components from dust, moisture, and debris, ensuring smooth operation, enhanced reliability, and extended service intervals. This sealing technology also supports the maintenance-free nature of the idler.Q: How does the idler contribute to operational efficiency?

A: Its abrasion-proof construction, powder-coated or painted finish, and maintenance-free performance reduce the frequency of shutdowns and repairs. The low noise level further enhances the operational environment, promoting continuous, efficient material handling.Q: What customization options are available for the Carrying Conveyor Idler?

A: You can select roller diameter, length, material (mild steel, HDPE, or rubber-coated), surface finish, color (standard black or customized), and speed to meet specific operational needs. Shell thickness can also be tailored from 3 mm to 10 mm based on application requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Conveyor Idler Category

Impact Conveyor Idler

Minimum Order Quantity : 10 Pieces

Type : Other, Impact Idler

Structure : Other, Roller Conveyor

Material : Rubber Coated Steel / Mild Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS